industrial scrap shredders

Product Description

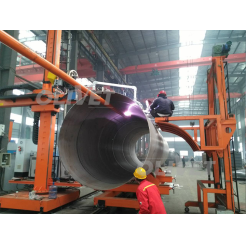

Industrial Scrap Shredders

We manufacture industrial scrap shredders for ferrous and non-ferrous materials

As a leading industrial scrap shredders manufacturer, we offer a full range of scrap metal crushing machines. Whether you need a pre-crusher, hammer mill metal shredder or downstream separation technology, all of our plants guarantee the highest level of cleanliness and purity in the final product.

Our industrial-grade metal shredder are perfect for processing:

Scrap metal recovered from end-of-life automobiles, complete cars, baled cars/baled scrap metal

Classified domestic light scrap, household appliances, building materials

Aluminum sheets, profiles and edges. ubc, brass, copper and non-ferrous materials.

Electric engines, white goods and incinerator bottom ash

Why You Should Choose a Qiansen Industrial Mmetal Scrap Shredder

Qiansen industrial scrap shredders are available in a wide range of sizes to best suit the required application. With outputs ranging from 4 tons per hour to over 60 tons per hour, the Scrap metal hammer mills are the most efficient small to medium sized shredders on the market and are the perfect solution for scrap yards and steel mills.

All Qiansen models come with a sturdy steel frame, eliminating the need for expensive foundations. What's more, they are fully assembled and tested before shipment, which means final assembly goes quickly and smoothly without incident.

Scrap Metal Shredders with Superior Performance

Our industrial scrap shredders are manufactured with a high level of attention to detail, designed to effectively handle the extreme rigors and stresses generated during the scrap shredding process.The Qiansen industrial scrap shredders are equipped with a variety of money-saving features, such as a heavy-duty ejector gate that releases unshreddable material before it causes excessive wear, a full set of disc rotors that reduce the cost of shredding per ton and the ability to adapt to a variety of automatic shredding modes. Depending on the type of material being shredded.